Overview

Interest in the environment is increasing around the world, and accordingly, interest in recycling is also increasing.

Among them, plastic is a very familiar material that is actively used in various industries such as plastic bags, straws, food containers, etc. as well as semiconductors and artificial skin, and is used almost everywhere. Therefore, the amount of waste is beyond imagination, and from 1950 to 2015, 6.3 billion tons of plastic was discarded. However, the proportion of actually recyclable plastics is lower than 15% out of the total, and it is the main culprit of environmental destruction.

There are hundreds of different types of plastics, depending on how they are manufactured, hence the recycling methods are all different. However, it is difficult for the human eye to distinguish plastics of almost the same color, so it is necessary to distinguish them in areas other than visible light such as near-infrared light. In addition, in order to distinguish the characteristics of the material, a camera with a wide wavelength band is required.

AVAL DATA CORPORATION(hereinafter referred to as Avaldata) released AHS-003VIR, a hyperspectral camera capable of spectroscopy from 450 to 1700 nm, in May 2021, which enables to distinguish plastics with various materials.

In order to help the understanding of the short wavelength hyperspectral camera, the basic knowledge of short wavelength infrared (SWIR) ray will be explained first, and the method of distinguishing various plastic materials and peripheral devices will be explained here.

1. Basic Knowledge about SWIR

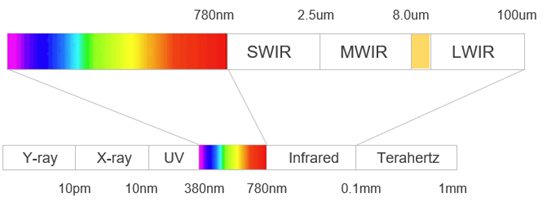

Figure 1. Wavelength band

The 380 nm to 780 nm region marked from purple to red is actually visible light that can be recognized by the human eye. If the wavelength is wider than that of visible light, it is possible to identify features that the human eye cannot see.

Figure 2. Visible light/SWIR images of an apple

When looking at an apple in visible light, it is a normal apple, but when it is captured by SWIR camera, bruises that are invisible in visible light are visible.

Figure 3. Visible light/SWIR images of candies

As shown in the image on the left in Figure 3, in the case of candy photographed with visible light, it can be distinguished by color and shape. However, it is actually a mixture of two different types of candy. When shooting with SWIR camera, it can be seen that two different types of candy are distinguished as shown in the right image of Figure 3.

2. SWIR & Hyperspectral Camera

Since the hyperspectral camera was developed based on the SWIR camera, before explaining the hyperspectral camera, we learned about the SWIR. Let us talk about cameras

Figure 4. (Up) ABA-003(013)VIR SWIR Camera / (Down) AHS-003VIR Hyperspectral Camera

The ABA-003(013)VIR is equipped with Sony’s IMX990/991 InGaAs sensor and has a pixel size of 5um. The ABA-003VIR can shoot at a resolution of 0.3M, up to 258fps, and the ABA-013VIR at a resolution of 1.3M, up to 134fps.

It is a VIS-SWIR camera that responds from the visible region to the near-infrared region of the wavelength band from 400 to 1700 nm, and the sensor itself has a built-in TEC1 cooler.

Equipped with a TEC1 cooler, it enables to capture higher quality images with lower dark current noise

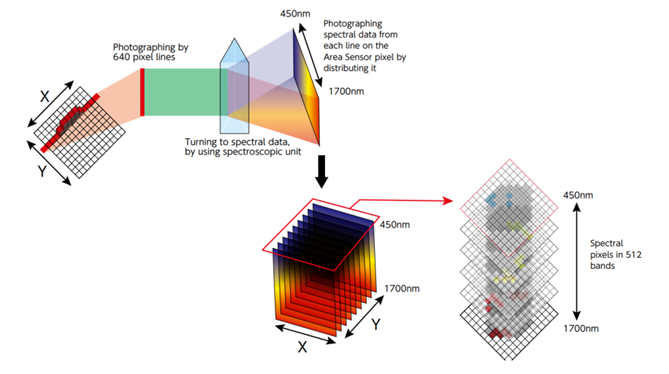

Figure 5. Fundamentals of hyperspectral imaging

In addition, the AHS-003VIR camera, which is a camera that acquires image data of 1 line, converts it into spectral data in the spectral unit, and transmits it to the area sensor, with the spectral wavelength to the sensor every 10.5 nm per line in 512 bands when 1 line is generated.

When capturing image with a hyperspectral camera, the characteristics of each wavelength band can be grasped at once.

| Company | Model | Wavelength Range | Band | Frame Rate |

| Company A | A | 900 ~ 1700nm | 328 | Max. 249fps |

| Company B | B | 900 ~ 1700nm | 224 | 670fps(Full Band)

15,000fps(4 Band) |

| Avaldata | AHS-U20MIR | 1300 ~ 2150nm | 96 | Max. 867fps |

| AHS-003VIR | 450 ~ 1700nm | 512 | 240fps (Full band)

450fps (256 band) 2,116fps (4 band) |

Figure 6. Specification comparison with other makers

Compared to other companies, Avaldata’s hyperspectral camera has a high wavelength (up to 2150 nm), a wide spectrum wavelength, and a large number of bands.

3. Utilization Method (distinguishing different plastic materials)

The inspection example below is a case in which plastics, which are difficult to analyze differences in visible light, are identified using spectral analysis of a hyperspectral camera.

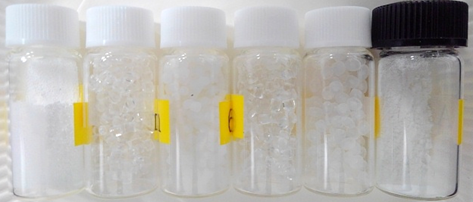

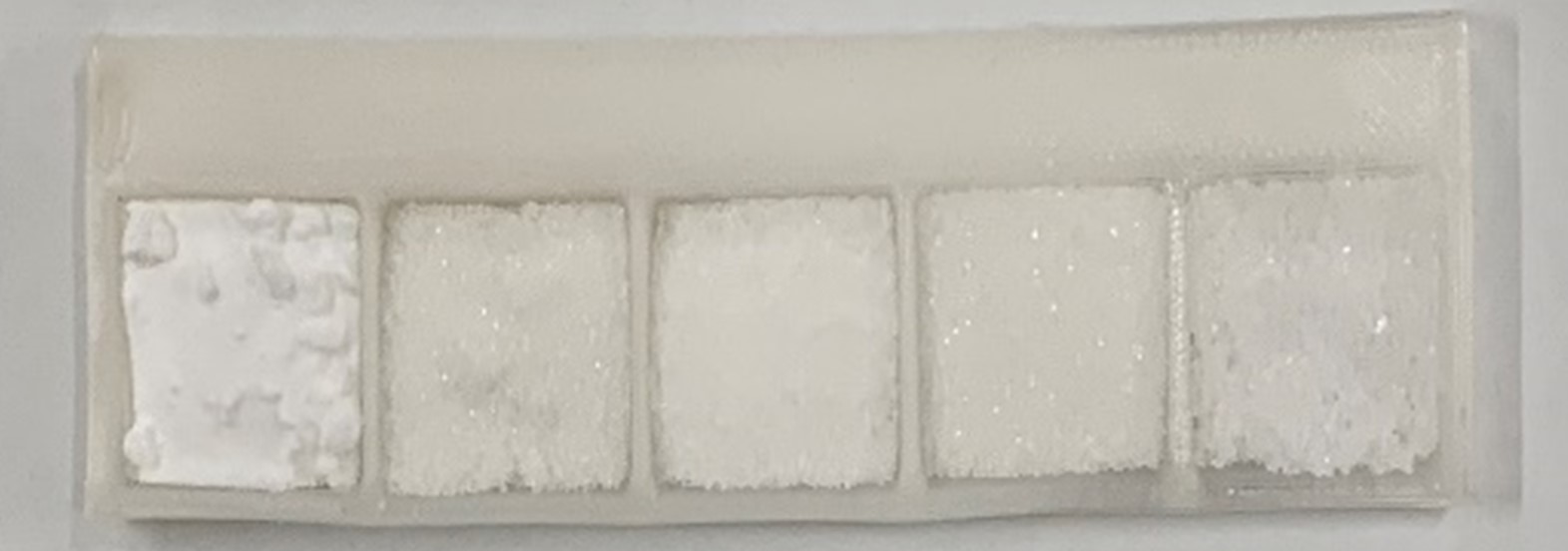

Figure 7. (From left to right) PVC/PS/Nylon/PC/PP/ABS

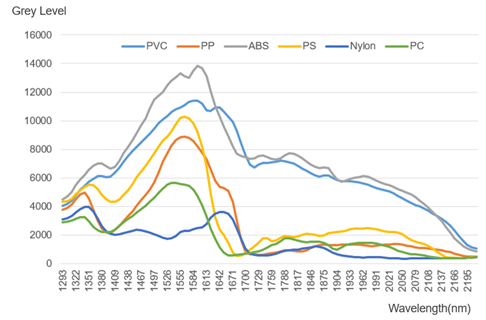

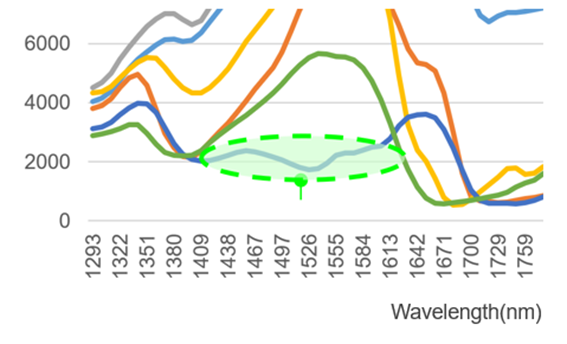

Figure 8. Spectrograph of PVC/PS/Nylon/PC/PP/ABS

The above spectral information can be obtained with a hyperspectral camera, and by using this, Nylon, PS, PC and PP can be distinguished, and materials can be classified by analyzing and using the wavelength band that absorbs light.

Figure 9. Spectrograph of Nylon

In the graph of Figure 8, Nylon is a spectral curve that responds with the lowest brightness than other plastics. Looking at the Nylon spectral graph, it can be seen that the brightness is the lowest at 1400~1600nm. Here, a low brightness means that light is absorbed well in the corresponding wavelength band.

Also, looking at the graph, it can be seen from Figure 9 that only Nylon can be distinguished separately because there is no other material that exhibits a brightness similar to that of Nylon

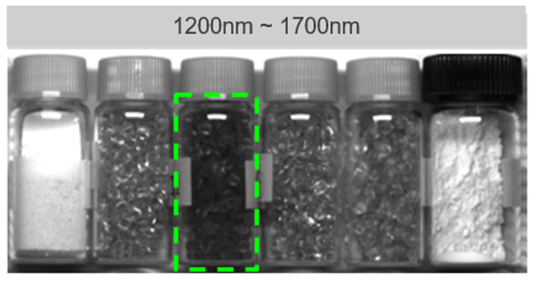

Figure 10. Nylon image after using filter

Nylon can be identified when an image is taken with a SWIR camera by applying a filter of 1200 to 1700 nm, including 1400 to 1600 nm. The green box in Figure 10 is Nylon.

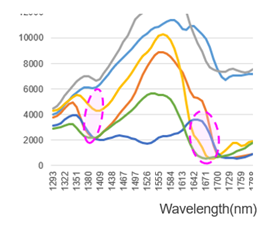

Figure 11. Spectrograph of PS, PC, PP

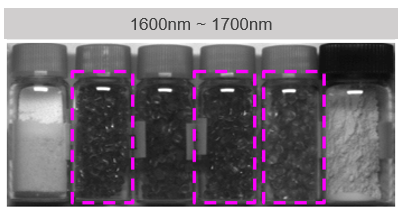

Figure 12. PS, PC, PP images after using filter

Secondly, in the case of PS, PC, PP, it can be seen that light is absorbed in two places (about 1400 nm wavelength band and about 1650-1700 nm wavelength band) as shown in Figure 11.

However, since the brightness of PC and PP are similar at about 1400nm, when comparing images by applying a filter in the 1600~1700nm band as shown in Figure 12 below, three materials can be distinguished. The difference between PS and PC will be larger.

Therefore, each plastic material can be analyzed with a single shot of the hyperspectral camera, which makes it possible to distinguish between recyclable and difficult-to-recycle plastics.

Also, as shown in Figure 13 below, when using with Aval Data’s dedicated software HySight, it is possible to display the color of the result, making it easier to distinguish the material.

Figure 13. Color images acquired by HySight S/W

(From left to right. Salt, sugar, MSG, citric acid and sodium bicarbonate)

4. Selection Method of Lens and Lighting

Since the spectral wavelength of hyperspectral is wide, it is necessary to select the appropriate product for lighting and lenses.

When using AHS-003VIR, if the customer’s application does not require only a specific part of the wavelength, the lens should also correspond to 450~1700nm.

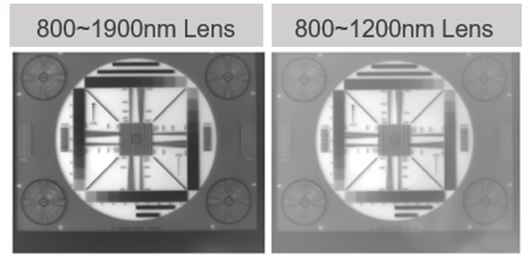

Figure 14. Image acquired using 1500nm lighting

For example, if you need a wavelength of 1500 nm, you need to use a lens that supports 1500nm.

As shown in Figure 14, when a lens corresponding to 800-1200nm is used and 1500nm illumination is used, the light is attenuated and the contrast may be lowered.

There are two main types of lighting used in near-infrared light: LED and halogen lighting.

Figure 15. LED and halogen lighting (From up to down)

In the case of LED lighting, it has low heat generation, low power consumption and longer lifespan compared to halogen, and can use a limited range in a specific wavelength band. However, compared to halogen, the amount of light is insufficient and a single LED light cannot use a wide wavelength band. Nevertheless, it is the most used lighting in the FA field which requires a long use time.

In the case of halogen lighting, the amount of light is higher, and the wavelength is wider than that of LED lighting. However, compared to LEDs, they have a shorter lifespan and high heat generation. Nevertheless, it is an essential illumination for spectroscopic analysis.

Consequently, the lens and lighting must be selected according to the application for which detection is desired.

Conclusion

The hyperspectral camera has the characteristic of making non-destructive inspection possible through the analysis of spectral characteristics.

For this reason, despite the high price, more and more companies are developing high-spectral cameras using a wide spectral wavelength band for non-destructive testing of various materials.

In the future, industry experts expect that non-destructive testing through spectral analysis will be activated for near-infrared applications with high added value in the industries like semiconductor panels, micro LED, food, cosmetics, and pharmaceuticals.

We Avaldata (www.avaldata.co.jp / www.aval-global.com) have supported the establishment of a system optimized for the customer’s environment by responding to the customization of the hyperspectral camera as well as suggesting and setting up lightings and lenses suitable for applications.

ENG

ENG KOR

KOR CHN

CHN JPN

JPN